| 00:00:00 | I have been fascinated by 3D printed compliant mechanisms for a really long time but when I saw Mark robber's recent video on the subject it seemed like a message from the universe that I needed to incorporate one of those into my own |

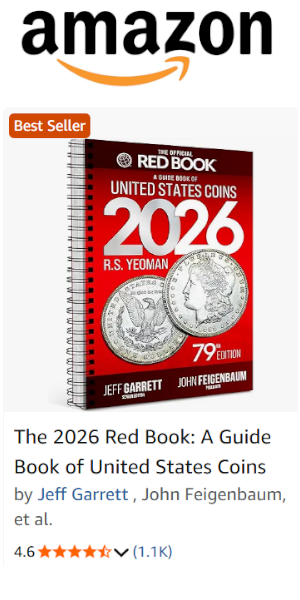

| 00:00:13 | design hello everyone and welcome back to the channel if you've been following along you know that I'm trying to build a robot that's capable of sorting coins by date if I can do that I should be able to easily find coins to add to my |

| 00:00:28 | own collection one of the challenges I face though is building a part that's capable of holding on to a coin and rotating it between two cameras so that both sides of the coin can be photographed at once and identified over |

| 00:00:42 | the last few videos I've showed some of the challenges I faced when designing that part and in this video we're going to improve the design by incorporating a compliant mechanism after watching Mark robber's video I began thinking about |

| 00:00:54 | compliant mechanisms and how those would actually work the problem was that I didn't really know how to design any of these things so I had to start making different versions just so I could |

| 00:01:07 | understand it this was my first attempt and I really like this idea and it seemed to work okay we're getting some good action here but as you can see there are some issues there because those Springs actually broke off the |

| 00:01:24 | edge of the workpiece there so we're actually only having these two Springs down here connected and those are the only one that are actuating the the piece but I I was I felt like I was on the right track it was nice because this |

| 00:01:40 | would have taken uh what this would have been two pieces just for this little section of the coin slider but I was actually able to print it all in one go um so I felt like I was on the right track the problem was that I didn't |

| 00:01:56 | really know how to design compliant mechanisms to do EX exactly what you wanted so I had to do some testing so I began iterating on it and the first few designs I had were were to kind of go on that theme but I |

| 00:02:12 | was really making them too complicated you can see that I was trying to make a spring shape here and a spring shape down here but that ends up these ended up being too thick and it actually takes much too much force to push down on this |

| 00:02:31 | in order to get it to Spring back um so I tried making thinner versions of those Springs and again it it just required too much force to squeeze those together and they weren't really coming back into |

| 00:02:49 | position so I began thinking about better ways of doing that what I came up with next was to try to put a diagonal brace along here but anyone who does any engineering understands that that |

| 00:03:08 | anything at an angle like this is actually kind of structural and no matter how hard you press on this it really does not give at all there's no spring at all to that and that's because this distance across the hypotenuse here |

| 00:03:23 | is actually wider than the distance across here and as I got thinking about that I was like I made a really strong structural piece but that doesn't do what I want it to do it's it doesn't have that compliance that I need in |

| 00:03:35 | order to grab onto a penny and again I tried to make it thinner but all that did was just end up deforming the piece in three dimensions |

| 00:03:52 | because these structural bars are just too strong they don't want to comply and they're the wrong shape so it actually forces it out of two-dimensional space and into 3D space because those parts |

| 00:04:08 | are so strong so obviously I was barking up the wrong tree with that idea for my next idea I thought I could just go straight across because this bar would be the same distance across there but again I made these a little |

| 00:04:24 | too thick and they don't really Bend as well as I'd like them to they ended up being structural as well the thing that I did like was that you could print this in place so that this in theory could slide up and |

| 00:04:38 | down but and these were these Center portions here were attached so in theory you should be able to get some compliance there but again no matter how hard I push you have to push way too hard on this in order to get any action |

| 00:04:54 | at all on that so that's not quite what we're looking for so I thought that maybe I just made made these a little bit too thick so I started to go thinner um in this version I went a little bit thinner and kind of got some |

| 00:05:09 | goop here from my printer didn't come out that great this one just seems a little too sloppy and again it is I don't know if you can see it or not but it's it's pushing these these sides in it's pulling those in when we press down |

| 00:05:26 | on this so this is starting to work and when when I press on this we're getting some compliance which is heading in the right direction but when I let go you can see that doesn't really spring back so you can see in this area right there |

| 00:05:42 | that that is not going back to its original shape which we would need it to do in order to maintain positive control of the penny at all times so although we're getting some compliance it's not quite right because it doesn't have |

| 00:05:55 | enough spring to return back to its original shape and I tried one more time making everything just a little bit thinner including the spaces in between the lines here but again this deforms but doesn't spring back to its original |

| 00:06:13 | shape so we're close here but not quite right again I'm just very happy that I could get the tolerances correct along these lines so that I can print in place have some U not stick together along the edge there but still have some |

| 00:06:30 | compliance so we're we're on the right track the next idea I had was to um make that space curved and this was starting to work a little bit better again you have to put quite a bit of force on that in order to |

| 00:06:51 | have any compliance but as you can see it's already starting to come back to its original shape so that's a really nice feature of this this particular design it's compliant and it returns back but again in this version this |

| 00:07:06 | version of the coin slider um I believe that these are just a little too thick and it requires too much force to actually push this down into place and we don't want that we want it to be a little easier to move down and then when |

| 00:07:22 | we release we want it to return back to its original shape and so I ended up with this version I made these center pieces just a little bit thinner and I'm pretty happy with the |

| 00:07:36 | way that this turned out we can see that we have pretty good compliance there and we're getting a good spring action again these parts are moving inwards as we pull down but when you release this these pull back and it actually helps |

| 00:07:54 | this to come back into position a little bit better so it's not it's not perfect but it is much better than the the other version so we're getting a much better return uh spring back to normal now in this version there's some |

| 00:08:09 | compliance there some springiness there and it doesn't take too much force to push down and it also returns back to its original position pretty well um this design really doesn't hold |

| 00:08:25 | on to anything the penny just kind of floats in there so I got thinking about that and what we could do is we could create just uh compliance in the top portion of that but that would mean that we would have to push down on this in |

| 00:08:40 | order to hold on to the penny um if only if only half of this were compliant if say the top half were compliant we could push down on this and it would hold on to the penny but we would need to keep that pressure on the |

| 00:08:55 | top of this in order to hold the penny and like I said in the last few videos I actually want the penny to be held by default and released only when we press on the bar but we can take what we learned in the last few videos about |

| 00:09:09 | working in three dimensions and we can create a part that actually works H this isn't really working on camera I'm going to print this out again in black and red so that you can see the different layers a little bit |

| 00:09:24 | better all right and this basically shows the new design and how that should work we have another part here that we can put into position that actually just snaps into |

| 00:09:43 | place and now this is still compliant so you can see that you have to push down on this bar in order to release the penny and it returns basically back into position but when we have a penny in there it holds |

| 00:09:58 | the penny by default and you have to push on the bar in order to release it so this is a promising design I think this is going to end up being my finished work and again we have some compliance here that Springs back into |

| 00:10:13 | action and we only need that to move just a little bit so it doesn't have to come back fully into position it just needs to hold the penny and be able to release it so there's really only a fraction of a |

| 00:10:26 | millimeter that that needs to move and return again I'll show you what that looks like hold the penny in position again when we push down on this bar that releases the penny so I'm pretty happy with this I think this is going to |

| 00:10:43 | be a really good design you can see that this has full thickness here and here so we can hold positively hold on to the penny and uh these pieces normally snap together so but I think I'm going to |

| 00:11:00 | actually end up putting a little bit of super glue in the corners here to hold this piece in place so we're basically going to put one of these in each one of the positions in the coin slider and when we want to release a penny we will |

| 00:11:16 | we will push down on this lever again there's going to be a follower that goes along the outside edge here and we will have cams on the outside edge here that push down on this bar when we want to release the penny I'll show you how that |

| 00:11:31 | works in more detail in a later video but I just wanted to show you this because I'm pretty excited about how this all turned out now oddly I don't think I reduced the part count all that much but I think I'm getting closer to |

| 00:11:44 | being able to print a part like this completely in place if anyone knows of any resources about how to design compliant mechanisms for 3D printing please leave them down below in the comments because I'd really like to |

| 00:11:58 | learn more about about this if there's a better way to do this I would really like to learn it so please if you have any information about compliant mechanisms and 3D printers um please share that information with me because I |

| 00:12:11 | I still believe that I can make this better um but we're pretty close I I believe we're pretty close to the finished part and this is basically the way I want it to work we're going to make a little bit wider uh outside edge |

| 00:12:24 | on this so that the cam can follow that and push it down a little more easily but otherwise I'm pretty happy with the results here in the next video we're going to work on those cams that should help us work out the timing of the coin |

| 00:12:38 | grabbing and release mechanisms but for now that's my two cents thanks for watching everyone stay awesome hey everyone it's future me I just wanted to take a moment to say that I've been doing some work on our website at the |

| 00:12:46 | coinb.in collecting the latest developments and machine learning and get early access to my YouTube videos |